Newsletter N°3/2010 - State-of-the-art palletising sytem

Automatic palletising systems

Smipal APS series of automatic palletising systems sets a new standard in the palletization of cartons, packs, trays and bundles in general and enhances end-of-line operations in countless sectors: beverages, food, chemicals, pharmaceuticals, detergents, glass, paper and many more.

Flexibility for end-of-line logistics

.

Smipal division's automatic palletising systems offer higher flexibility if compared to traditional palletizers. The central column can be combined in different ways with standard pallet-handling modules, thus allowing the end user to widely customize the palletising system layout in order to adapt it to any end-of-line logistics, for both existing plants and new installations.

Smipal's palletizers can be easily fitted in any format, product and/or layout change and can provide different types of palletising patterns, according to the customer's specific needs.

The palletising process

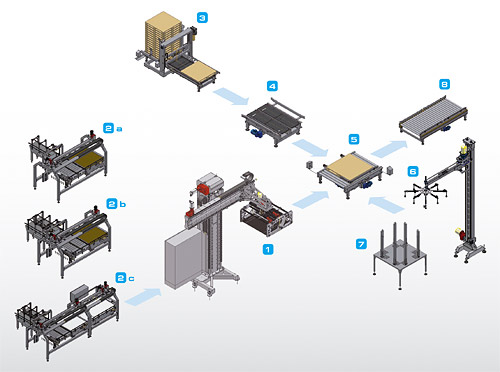

The palletising process takes place in multiple phases, requiring the combination of the central column of palletization (1) with different infeed and layer-preformation modules (2): single-entry infeed with simple preformation (2a), double-entry infeed with simple preformation (2b) or double-entry infeed with motorised preformation (2c). The palletising process also includes: the adjustable fork magazine for empty pallets (3), capable of loading the pallets from both directions and releasing them to the line both headways and sideways; the pallet chain conveyors (4), available in three different lengths; the 90° pallet translation module (5); the interlayer pad-inserting device (6); the pad magazine (7) and the pallet roller conveyors (8), available in different lengths.

.

High-tech palletisers

The APS series of palletising systems can be set in operational motion immediately, as each module is assembled, pre-cabled and tested in Smipal's factory before being delivered. This solution allows to dramatically reduce assembly and start-up operations at the customer's plant.

Furthermore, the entire system can be quickly "dismantled", transported and stored in small-sized areas, and then "re-mounted" and started up in less than 3 hours. Mechanical simplicity, use of robotic-like components and an optimised frame allow the end user to cut maintenance costs and energy consumptions drastically, as well as to extend the system's life cycle time.

We invite you to assess with our sales department the palletising solution that meets your requirements at best. Further information are available in the Smipal section of our web-site.

Marketing Department

SMI S.p.A.

E-mail: info@smigroup.it

www.smigroup.it

Contact us

- ООО СМИ РУССИА

- Address: д. Сосенки, ул. Сосновая, 1Б

офис 401-402

108803 Москва, п. Сосенское

Russia - Phone: + 7 495 720 67 97

- E-mail: sales.russia@smigroup.net

- Monday - Friday: 09:00 - 18:00

Saturday - Sunday: Closed

Privacy statement

DATA PROTECTION AND PRIVACY

The European Regulation 679/2016 (GDPR) on the protection of personal data has been fully applicable since May 25th, 2018. This is an important goal, because it lays down rules relating to the processing of personal data for all Countries within the Union. Every company of the SMI Group planned a series of activities, assets or operational modes to comply with the regulation and put into practice the protection of personal data. Here is a list of actions taken to comply with the European Regulation and our policy on personal data processing.

![]()

Lawfulness of processing

All activities relating to personal data processing shall be lawful (consent, contract obligations, vital interests of the data subject or of third parties, compliance with legal obligations to which the controller is subject, public interest or exercise of official authority, legitimate interest pursued by the controller or by third parties).

![]()

Information document

The information statement has been improved and updated to the new regulations (art. 13 and 14 GDPR).

![]()

Rights of the data subjects (right of access, right to erasure-right to be forgotten, right to restriction of processing, right to object, right to data portability)

Technical and organization measures have been adopted to ensure the data subject's exercise of his rights and to meet the data subject requirements.

![]()

Controllers, processors

Based on the new principle of “accountability”, SMI Group organization was re-defined, in order to proactively ensure integral compliance with the Regulation.

Redefinition of the role of data processors and service suppliers whose activity implies personal data processing.

![]()

Risk of data processing; accountability measures taken by controllers and processors (Impact assessment, record of processing activities, security of processing, data breach)

The “Conformity document”, including records of data processing activity, plans, adopts and demonstrates all technical and organizational measures taken to adequately perform the data processing activities and specifies the necessary procedures to be adopted to notify data breach.

![]()

Transfer of personal data to international organizations

Smi Group adheres to the general principles and guarantees concerning the transfer of personal data to third Countries.

The Controller is:

SMI S.p.A.

Head office: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

P.I.: 04471940165 - C.F.: 03942700166 - R.E.A.: 421708

For further information, write to: privacy@smigroup.net

According to the European Regulation 679/2016, the data subject is entitled to exercise the rights set forth in the Regulation.

The integral version of art. 15; 16; 17; 18; 20; 21; 77 of the European Regulation is attached to this document.

In order to exercise your rights, please send the application form duly filled in to the Controller's address.

Legal notice

SMI S.p.A. con Unico Socio

Società sottoposta a direzione e coordinamento da SMIGROUP S.p.A.

Società appartenente al GRUPPO IVA SMI INDUSTRIES

Sede amministrativa e Unità produttiva:

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.111 - Fax: +39 0345 40.209 - www.smigroup.it

C.F. 03942700166 - P. IVA IT04471940165 - R.E.A. 421708

Iscr.Reg.Imprese 03942700166 - Cap. Soc. € 5.000.000 i.v.

Sede legale: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA