New EBS KL ERGON: efficiency and sustainability in a small space

| |||

| Energy efficiency and environmental sustainability play a key role in the investment choices of every company. | |||

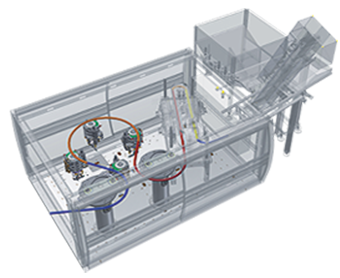

| At Drinktec trade fair, that will be held in Munich (Germany) from 12-16 September 2022, SMI will present the new EBS KL ERGON compact stretch-blow moulder for production requirements up to 2,500 bottles/hour per cavity.

Inspired by Industry 4.0 and Internet of Things (IoT) principles, the new EBS KL ERGON series, available in stand-alone, as well as in ECOBLOC® version (integrated with a rotary electronic filler and a rotary capper), is the ideal solution for the production of PET and rPET containers up to 25,000 bottles/hour. |  | ||

| |||

The advantages of EBS KL ERGON range at a glance

| |||

| Advanced technology in a small spaceThe new EBS KL blow moulder stands out for its ultra-compactness, made possible by the fact that the preform heating section and the stretch-blow moulding section are integrated in a single module. - space-saving design suitable even for small-sized bottling lines | ||

Environmental sustainable production processesThe stretch-blow moulding carousel of the new EBS KL blow moulders is equipped with motorized stretch rods, whose functioning, controlled by electronic drives, do not require pneumatic cams. - precise management of the stretch rod path and accurate control of its position |  | ||

| Maximum efficiency and precisionCam-free technology that allows to modify the stretch speed without mechanical interventions (cam replacement), as the servo-motor automatically adjusts according to the production speed. -reduction of the machine vibrations | ||

Energy saving and reduced maintenanceThe stretch-blow moulding system of the new EBS KL blow moulders are equipped with high-performance valves with low dead volumes (-50% compared to the previous models). -reduction of pre-blowing and blowing times, which ensures a higher performance of the machine and a better quality of the bottles produced |  | ||

| Fast and precise movements

New motion system of the grippers, based on preform/bottle grippers without springs, equipped with desmodromic cams. -technical innovation that optimizes the spaces and reduces the diameter in which the grippers move, which leads to a lower wear and a higher control precision of the blow moulder | ||

| For further information on the new EBS KL ERGON blowers, contact our sales department or visit our web site. | |||

Contact us

- ООО СМИ РУССИА

- Address: д. Сосенки, ул. Сосновая, 1Б

офис 401-402

108803 Москва, п. Сосенское

Russia - Phone: + 7 495 720 67 97

- E-mail: sales.russia@smigroup.net

- Monday - Friday: 09:00 - 18:00

Saturday - Sunday: Closed

Privacy statement

DATA PROTECTION AND PRIVACY

The European Regulation 679/2016 (GDPR) on the protection of personal data has been fully applicable since May 25th, 2018. This is an important goal, because it lays down rules relating to the processing of personal data for all Countries within the Union. Every company of the SMI Group planned a series of activities, assets or operational modes to comply with the regulation and put into practice the protection of personal data. Here is a list of actions taken to comply with the European Regulation and our policy on personal data processing.

![]()

Lawfulness of processing

All activities relating to personal data processing shall be lawful (consent, contract obligations, vital interests of the data subject or of third parties, compliance with legal obligations to which the controller is subject, public interest or exercise of official authority, legitimate interest pursued by the controller or by third parties).

![]()

Information document

The information statement has been improved and updated to the new regulations (art. 13 and 14 GDPR).

![]()

Rights of the data subjects (right of access, right to erasure-right to be forgotten, right to restriction of processing, right to object, right to data portability)

Technical and organization measures have been adopted to ensure the data subject's exercise of his rights and to meet the data subject requirements.

![]()

Controllers, processors

Based on the new principle of “accountability”, SMI Group organization was re-defined, in order to proactively ensure integral compliance with the Regulation.

Redefinition of the role of data processors and service suppliers whose activity implies personal data processing.

![]()

Risk of data processing; accountability measures taken by controllers and processors (Impact assessment, record of processing activities, security of processing, data breach)

The “Conformity document”, including records of data processing activity, plans, adopts and demonstrates all technical and organizational measures taken to adequately perform the data processing activities and specifies the necessary procedures to be adopted to notify data breach.

![]()

Transfer of personal data to international organizations

Smi Group adheres to the general principles and guarantees concerning the transfer of personal data to third Countries.

The Controller is:

SMI S.p.A.

Head office: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

P.I.: 04471940165 - C.F.: 03942700166 - R.E.A.: 421708

For further information, write to: privacy@smigroup.net

According to the European Regulation 679/2016, the data subject is entitled to exercise the rights set forth in the Regulation.

The integral version of art. 15; 16; 17; 18; 20; 21; 77 of the European Regulation is attached to this document.

In order to exercise your rights, please send the application form duly filled in to the Controller's address.

Legal notice

SMI S.p.A. con Unico Socio

Società sottoposta a direzione e coordinamento da SMIGROUP S.p.A.

Società appartenente al GRUPPO IVA SMI INDUSTRIES

Sede amministrativa e Unità produttiva:

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.111 - Fax: +39 0345 40.209 - www.smigroup.it

C.F. 03942700166 - P. IVA IT04471940165 - R.E.A. 421708

Iscr.Reg.Imprese 03942700166 - Cap. Soc. € 5.000.000 i.v.

Sede legale: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA