Compactness and sustainability at Anuga FoodTec

| |||

Compact and efficient end of line for the food industry | |||

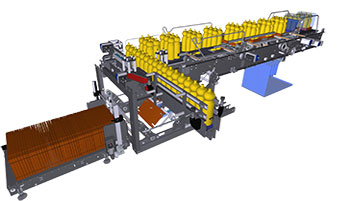

| At Anuga FoodTec 2022, that will be held from 26th to 29th April in Cologne (Germany), SMI will showcase an extremely compact, efficient and environmentally sustainable end-of-line system, composed of an ASW 30 T ERGON shrink wrapper with single-lane infeed and 90° product entry and of the APS 615 ERGON semi-automatic palletizer. The solutions showcased at Anuga FoodTec pack metal containers of tomato soup in 4x3 format in tray+100 % recycled film, that are then palletized by the new “mini-pal” at the speed of 15 packs/minute. | ||

| This system has been designed for those food manufacturers who do not require high speeds, have a reduced-size plant and a limited budget, but at the same time do not want to give up the advantages offered by Industry 4.0 and Internet of Things (IoT)- compliant advanced technologies.

| |||

| |||

Meet us at booth C088 Hall 5.1 | |||

THE ADVANTAGES OF THE ASW SERIES | |||

CompactnessThe ASW ERGON range is the ideal solution for packing a wide range of containers with a cylindrical, oval or square/rectangular base. Thanks to the single-lane infeed conveyor, a divider for channeling the product at the infeed is not required. The machine occupies very little space and easily adapts to the logistic conditions of any line layout.

|  | ||

| Ergonomics and safetyThe single-lane infeed facilitates the correct channeling of loose containers on the conveyor belt. Thanks to the rotary feeding device, the containers are moved from the single-lane conveyor to the multi-lane conveyor at the machine infeed. The pack formation is characterized by a double belt system, that, by means of an electronic cam, separates the products according to the format to be processed. The cardboard magazine (for P and T models), located in an easily accessible position for the operator, ensures an ergonomic, easy, fast and safe loading.

| ||

Flexibility and sustainabilityFormat changeover is easy and fast, as the adjustment of the guides of the different rows is not required. The film reel unwinding is controlled by a progressive brake, which ensures optimal film tensioning. The film splicing at the end of the reel is performed by a manual sealing bar and the cutting unit is equipped with a blade controlled by a direct-drive brushless motor, that ensures a precise cut and simplifies the maintenance. The model showcased at the trade fair uses a 100% recycled film with a 60 micron thickness, an environmentally sustainable solution for a high-quality pack. |  | ||

THE ADVANTAGES OF THE APS 615 ERGON MODEL | |||

| Compact and ergonomic structure

| ||

Easy flexibility and maintenance

-great operational flexibility -wide possibilities of customization, in order to adapt to the needs of format changeover, product changeover and/or plant layout. The electric panel is a separate module that is not unwired during the transport and can be immediately installed at the customer's premises.

|  | ||

| If you want to discover other advantages of SMI packaging solutions, we'll wait for you at Anuga FoodTec 2022 in Cologne at our booth C088, hall 5.1 or we invite you to contact our sales department. Marketing Department

| |||

Contact us

- ООО СМИ РУССИА

- Address: д. Сосенки, ул. Сосновая, 1Б

офис 401-402

108803 Москва, п. Сосенское

Russia - Phone: + 7 495 720 67 97

- E-mail: sales.russia@smigroup.net

- Monday - Friday: 09:00 - 18:00

Saturday - Sunday: Closed

Privacy statement

DATA PROTECTION AND PRIVACY

The European Regulation 679/2016 (GDPR) on the protection of personal data has been fully applicable since May 25th, 2018. This is an important goal, because it lays down rules relating to the processing of personal data for all Countries within the Union. Every company of the SMI Group planned a series of activities, assets or operational modes to comply with the regulation and put into practice the protection of personal data. Here is a list of actions taken to comply with the European Regulation and our policy on personal data processing.

![]()

Lawfulness of processing

All activities relating to personal data processing shall be lawful (consent, contract obligations, vital interests of the data subject or of third parties, compliance with legal obligations to which the controller is subject, public interest or exercise of official authority, legitimate interest pursued by the controller or by third parties).

![]()

Information document

The information statement has been improved and updated to the new regulations (art. 13 and 14 GDPR).

![]()

Rights of the data subjects (right of access, right to erasure-right to be forgotten, right to restriction of processing, right to object, right to data portability)

Technical and organization measures have been adopted to ensure the data subject's exercise of his rights and to meet the data subject requirements.

![]()

Controllers, processors

Based on the new principle of “accountability”, SMI Group organization was re-defined, in order to proactively ensure integral compliance with the Regulation.

Redefinition of the role of data processors and service suppliers whose activity implies personal data processing.

![]()

Risk of data processing; accountability measures taken by controllers and processors (Impact assessment, record of processing activities, security of processing, data breach)

The “Conformity document”, including records of data processing activity, plans, adopts and demonstrates all technical and organizational measures taken to adequately perform the data processing activities and specifies the necessary procedures to be adopted to notify data breach.

![]()

Transfer of personal data to international organizations

Smi Group adheres to the general principles and guarantees concerning the transfer of personal data to third Countries.

The Controller is:

SMI S.p.A.

Head office: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

P.I.: 04471940165 - C.F.: 03942700166 - R.E.A.: 421708

For further information, write to: privacy@smigroup.net

According to the European Regulation 679/2016, the data subject is entitled to exercise the rights set forth in the Regulation.

The integral version of art. 15; 16; 17; 18; 20; 21; 77 of the European Regulation is attached to this document.

In order to exercise your rights, please send the application form duly filled in to the Controller's address.

Legal notice

SMI S.p.A. con Unico Socio

Società sottoposta a direzione e coordinamento da SMIGROUP S.p.A.

Società appartenente al GRUPPO IVA SMI INDUSTRIES

Sede amministrativa e Unità produttiva:

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.111 - Fax: +39 0345 40.209 - www.smigroup.it

C.F. 03942700166 - P. IVA IT04471940165 - R.E.A. 421708

Iscr.Reg.Imprese 03942700166 - Cap. Soc. € 5.000.000 i.v.

Sede legale: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA