Combined packers with in-line infeed

LCM ERGON Series

LCM 30 ERGON - Combined packers up to 30 ppm

LCM ERGON series automatic machines combine in one system the functions provided by wrap-around packers and shrink wrappers, for the packaging of plastic, metal, cardboard and glass containers in closed cases, on cardboard pad + film, on cardboard tray + film and on cardboard tray only.

LCM ERGON series packing machines run up to 40 packs per minute, depending on the product handled and on the packing pattern.

Different pack collations can be formed according to the container’s shape, capacity and dimensions; the most popular formats on market are 2x3, 3x4 and 4x6 in closed boxes, 4x3 and 6x4 on tray+film.

LCM 30 ERGON packers are equipped with a mechanical product-grouping system and can be configured with either in-line or 90° in-feed conveyor belts, depending on the customer’s requirements. The format changeover is manual.

| LCM 30 ERGON | |

|---|---|

| Speed (PPM) | 30 |

| Packaging Type | Tray + film Tray only Wrap-around case Wrap-around tray |

| Lanes | 1 |

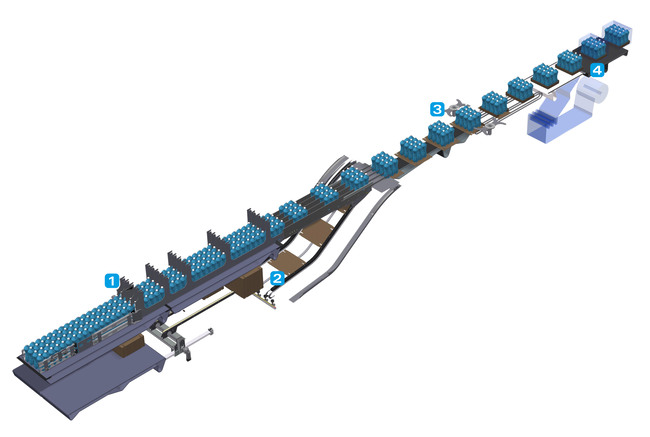

1At the machine infeed a motorized oscillating sorter lines up loose containers along a conveyor belt featuring low-friction chains made of thermoplastic material. In the pack-forming unit products are grouped in the chosen packing pattern by means of a pneumatic (LCM 30) or electronic (LCM 40) device.

2In case of packaging in closed case or tray, a sheet of corrugated cardboard is picked from the blank magazine by an alternate-motion picker with vacuum suckers; the carboard blank is then carried up along the blank ramp and positioned under the incoming pack collation with short leading side (wrap-around case) or long leading side (tray).

3Depending on the packaging features, in the case/tray forming unit the cardboard blank is folded and wrapped around the products by means of special guides. Later on flap-folding devices fold first side flaps and then upper/lower flaps on both the front and the back of the pack. Hot-glue sealing makes the case highly resistant.

4In case of packaging in film, the film is wrapped around and overlapped under the pack in transit towards the shrinking tunnel. The unwinding of film reels - positioned in the lower part of the machine – is adjusted by a progressive brake which provides constant film tensioning.

- Machine bearing frame made of sand-blasted and powder-painted steel

- Sliding protection doors in anodised aluminium featuring a rounded shape which let all the motors (featuring low energy consumption) be placed externally if compared to the mechanical groups they activate. The closing system of doors is equipped with a slow-down device, which accompanies the door smoothly in its final phase of closure

- Absence of gearboxes and prevailing employment of ICOS brushless motors equipped with digital servo-driver integrated into the motor

- For life lubricated bearings

- Infeed conveyor with chains made of thermoplastic material featuring low friction coefficient and a motorized system of oscillating laning guides

- Cardboard magazine situated beneath the infeed conveyor in an easily accessible position (P and T models)

- Alternate motion cardboard blank picker, equipped with suckers

- Before the pack enters the shrinking tunnel, the film is cut by a knife equipped with motorized blade and then wrapped around the group of containers and overlapped on the bottom of the pack. The adjustment of the film length is electronic

- The shrink tunnel features state-of-the-art technical solutions that enables the energy consumption reduction and the maximum environmental compatibility of the processes. Thanks to the precise analysis of thermodynamic phenomena generated by the shrink process, the tunnel distributes hot air flows in an efficient and homogeneous way on the pack, thus ensuring the excellent quality of the final pack. Shrink resistances are positioned on the side walls of the tunnel.

- Heat-shrinking tunnel with forced air ventilation

- Interactive touchscreen display with intuitive graphics

Modular design

SMI machines are designed according to advanced principles of module assembly and feature interchangeable mechanical and electronic components, which ensure a reduction of the down-times during technical interventions or programmed maintenance and the optimization of the use of spare parts on stock.Operational flexibility

These machines can package a wide range of products in several pack collations, so as to effectively meet the end user's current and future requirements. Moreover, each machine can be equipped with additional devices, which increase its basic functions and ensure a high level of customization of the final package.Motors directly connected to the drive shafts

SMI machines do not include gearboxes: the motors are directly connected to the drive shafts. The consequent advantage is the reduction of maintenance, energy consumption and noise.Easy and cost-saving maintenance

The rounded safety doors enable to have more space inside the machine and thus to install motors externally compared to the mechanical units they drive, which allows the operator to easily perform the activities connected to the plant maintenance.Constant film tensioning

Film reels placed in the lower part of the machine with film unwinding controlled by a progressive brake and constant film tensioning ensured by a system provided with a tensioning springPrecise and automatic film cut

Film-cutting unit equipped with direct drive motorization that allows to easily carry out motor maintenance and reduce maintenance operations.Perfect cases

SMI case packers are equipped with fixed guides, which press the pack walls at the machine outlet. This system ensures a perfectly balanced, resistant case, whereas the rotary chain pressing systems can not guarantee the same quality level.User-friendly man-machine interface

The POSYC® control panel, fixed or sliding on a boom running the whole length of the machine (depending on the machine model), enables even less expert operators to easily and effectively run the packer, thanks to an intuitive interface, a touch screen display and diagnosis functions and real-time technical support available on the POSYC®.Images are for illustrative purposes and data are not binding, as they have to be confirmed by SMI according to the machine user's production conditions and technical specifications.

Contact us

- ООО СМИ РУССИА

- Address: д. Сосенки, ул. Сосновая, 1Б

офис 401-402

108803 Москва, п. Сосенское

Russia - Phone: + 7 495 720 67 97

- E-mail: sales.russia@smigroup.net

- Monday - Friday: 09:00 - 18:00

Saturday - Sunday: Closed

Privacy statement

DATA PROTECTION AND PRIVACY

The European Regulation 679/2016 (GDPR) on the protection of personal data has been fully applicable since May 25th, 2018. This is an important goal, because it lays down rules relating to the processing of personal data for all Countries within the Union. Every company of the SMI Group planned a series of activities, assets or operational modes to comply with the regulation and put into practice the protection of personal data. Here is a list of actions taken to comply with the European Regulation and our policy on personal data processing.

![]()

Lawfulness of processing

All activities relating to personal data processing shall be lawful (consent, contract obligations, vital interests of the data subject or of third parties, compliance with legal obligations to which the controller is subject, public interest or exercise of official authority, legitimate interest pursued by the controller or by third parties).

![]()

Information document

The information statement has been improved and updated to the new regulations (art. 13 and 14 GDPR).

![]()

Rights of the data subjects (right of access, right to erasure-right to be forgotten, right to restriction of processing, right to object, right to data portability)

Technical and organization measures have been adopted to ensure the data subject's exercise of his rights and to meet the data subject requirements.

![]()

Controllers, processors

Based on the new principle of “accountability”, SMI Group organization was re-defined, in order to proactively ensure integral compliance with the Regulation.

Redefinition of the role of data processors and service suppliers whose activity implies personal data processing.

![]()

Risk of data processing; accountability measures taken by controllers and processors (Impact assessment, record of processing activities, security of processing, data breach)

The “Conformity document”, including records of data processing activity, plans, adopts and demonstrates all technical and organizational measures taken to adequately perform the data processing activities and specifies the necessary procedures to be adopted to notify data breach.

![]()

Transfer of personal data to international organizations

Smi Group adheres to the general principles and guarantees concerning the transfer of personal data to third Countries.

The Controller is:

SMI S.p.A.

Head office: Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

P.I.: 04471940165 - C.F.: 03942700166 - R.E.A.: 421708

For further information, write to: privacy@smigroup.net

According to the European Regulation 679/2016, the data subject is entitled to exercise the rights set forth in the Regulation.

The integral version of art. 15; 16; 17; 18; 20; 21; 77 of the European Regulation is attached to this document.

In order to exercise your rights, please send the application form duly filled in to the Controller's address.

Legal notice

SMI S.p.A. con Unico Socio

Società sottoposta a direzione e coordinamento da SMIGROUP S.p.A.

Società appartenente al GRUPPO IVA SMI INDUSTRIES

Sede amministrativa e Unità produttiva:

Via Carlo Ceresa, 10 - 24015 San Giovanni Bianco (BG) - ITALIA

Tel. +39 0345 40.111 - Fax: +39 0345 40.209 - www.smigroup.it

C.F. 03942700166 - P. IVA IT04471940165 - R.E.A. 421708

Iscr.Reg.Imprese 03942700166 - Cap. Soc. € 5.000.000 i.v.

Sede legale: Via Monte Grappa, 7 - 24121 Bergamo (BG) - ITALIA